Frequently Asked Questions

Everything you need to know about 3D concrete printing and how Lyco Integrated can bring your vision to life.

Get answers to the most common questions about our 3D concrete printing technology, processes, and how we can help with your construction project.

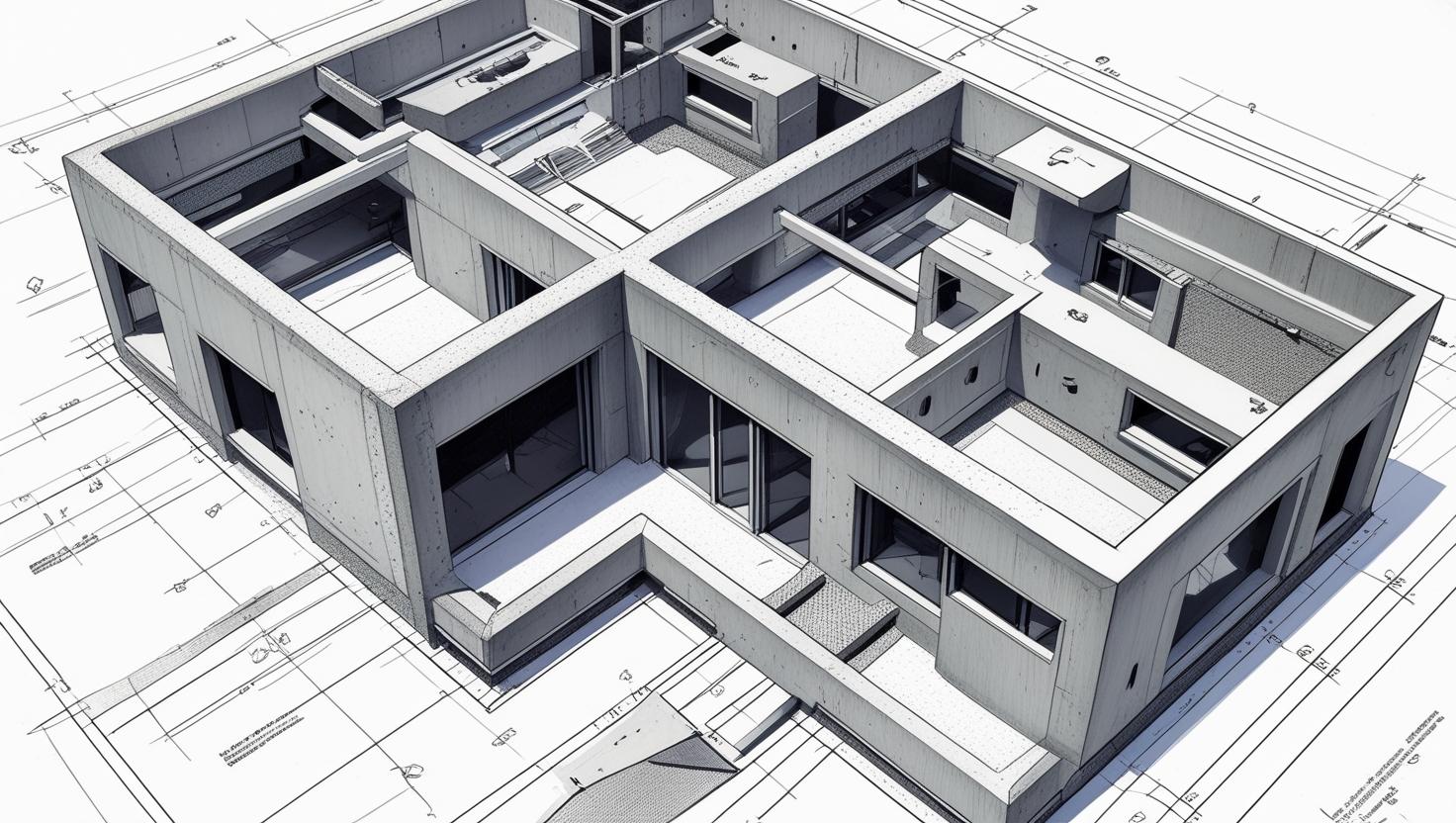

3D concrete printing, also known as additive construction or concrete printing, is a revolutionary construction technology that uses large-scale 3D printers to deposit concrete material layer by layer to create building structures. This process follows a digital blueprint to construct walls, foundations, and architectural features with precision.

Our advanced concrete printing systems can create complex geometries, integrate utilities during construction, and produce structures that are often stronger and more durable than traditional construction methods. The technology allows for unprecedented design freedom while significantly reducing construction time and material waste.

Key Technologies:

- Large-format robotic printing systems

- Specialized concrete formulations

- Real-time quality monitoring

- Integrated utility placement

Our 3D concrete printing process follows four streamlined phases designed to deliver your project efficiently:

1. Site Assessment

We conduct comprehensive site evaluation, soil analysis, and utility mapping to ensure optimal printer placement and structural requirements.

2. Design Optimization

Our engineers convert your architectural plans into printer-optimized designs, incorporating structural requirements and utility integration.

3. Printing & Construction

On-site 3D printing with continuous concrete flow, integrated utilities, and real-time quality monitoring throughout the build process.

4. Quality Assurance

Final inspection, finishing work, and comprehensive testing to ensure structural integrity and building code compliance.

Our 3D concrete printing technology is versatile and can construct a wide range of structures across residential, commercial, federal, and institutional sectors:

Residential

- • Single-family homes

- • Multi-unit housing

- • Custom bathtubs

- • Swimming pools

- • Fire pits & fencing

Federal

- • Seawalls & barriers

- • Military housing

- • Emergency shelters

- • Infrastructure projects

- • Government facilities

Institutional

- • Churches & worship

- • Community centers

- • YMCA facilities

- • Educational buildings

- • Healthcare facilities

Commercial

- • Casino interiors

- • Retail spaces

- • Hospitality venues

- • Office buildings

- • Entertainment facilities

Project timelines vary based on size, complexity, and type, but 3D concrete printing typically delivers structures 60-80% faster than traditional construction methods:

Residential Homes

1-3 weeks for printing phase

vs. 3-6 months traditional

Commercial Projects

2-8 weeks for printing phase

vs. 6-12 months traditional

Large Infrastructure

1-6 months for printing phase

vs. 1-3 years traditional

Total project time includes design, site preparation, printing, finishing, and inspections. Actual timelines depend on project complexity, weather, and permit approvals.

3D concrete printing offers significant advantages over traditional construction methods across multiple dimensions:

Speed & Efficiency

60-80% faster construction with 24/7 printing capability

Superior Strength

Enhanced structural integrity with optimized material distribution

Design Freedom

Complex geometries impossible with traditional methods

Sustainability

70% less material waste and reduced carbon footprint

Cost Efficiency

Reduced labor costs and material waste savings

Quality Control

Consistent precision with real-time monitoring

Yes, 3D printed concrete structures meet or exceed traditional construction safety and durability standards. Our printed structures undergo rigorous testing and comply with all building codes:

Safety Standards

- • Building code compliance

- • Structural engineering certification

- • Fire resistance testing

- • Seismic safety analysis

- • Third-party inspections

Durability Features

- • Enhanced concrete formulations

- • Optimized layer bonding

- • Weather resistance

- • 100+ year lifespan

- • Minimal maintenance required

Case Study: Our Gulf Coast seawall project has successfully withstood Category 4 hurricane conditions, demonstrating the exceptional durability of our 3D printed structures.Learn more →

3D concrete printing costs vary by project size, complexity, and location. However, most clients experience significant savings compared to traditional construction:

20-40%

Cost savings vs. traditional construction

60-80%

Reduced labor costs

70%

Less material waste

Factors affecting cost:

- • Project size and complexity

- • Site accessibility and preparation

- • Custom design requirements

- • Geographic location

- • Finishing and utility integration

Free Consultation: Contact us for a detailed cost analysis and quote for your specific project.Get a quote →

Lyco Integrated provides 3D concrete printing services across North America, with specialized capabilities for projects of all sizes:

Primary Service Areas

- • United States (all 50 states)

- • Canada (major provinces)

- • Federal territories and bases

- • Remote and challenging locations

Specialized Services

- • Emergency response deployment

- • Disaster relief construction

- • Military and federal projects

- • International consulting

Our mobile printing units can be deployed to virtually any location with road access. For remote or challenging sites, we provide specialized logistics and site preparation services.

Starting your 3D concrete printing project is straightforward with our streamlined consultation process:

Initial Consultation

Contact us for a free consultation to discuss your project vision, timeline, and requirements.

Site Assessment

Our team conducts a comprehensive site evaluation and feasibility analysis.

Proposal & Planning

Receive detailed project proposal with timeline, costs, and technical specifications.

Project Execution

Begin construction with regular updates and quality monitoring throughout the process.

Still Have Questions?

Our team of experts is ready to discuss your specific project needs and answer any questions about 3D concrete printing technology.